In-Circuit Test (ICT)

In-Circuit Test (ICT) is an electrical test which quickly processes printed circuit boards (PCBAs) at a high speed to determine if the board was manufactured properly. This test methodology involves three key components: a tester, a fixture, and software program. ICT verifies that all required components are installed correctly on the printed circuit board. If a failure occurs during an In-Circuit Test, a printout receipt directs test operators to the exact point of failure to help resolve a manufacturing defect. Other tests that can be performed at ICT include LED testing, Analog to Digital and Digital to Analog Converter testing, and others.

To date, SSP has completed 4,600+ turnkey ICT Fixture/Program projects for our customers. Our ICT project experience ranges from PCBAs having less than 100 nets to 10,000+ nets involving some of the most advanced technologies. Whether you're in need of a single ICT fixture/program, or multiple different PCBA's making a product family, SSP is here to deliver quality and reliable solutions.

ICT Testers

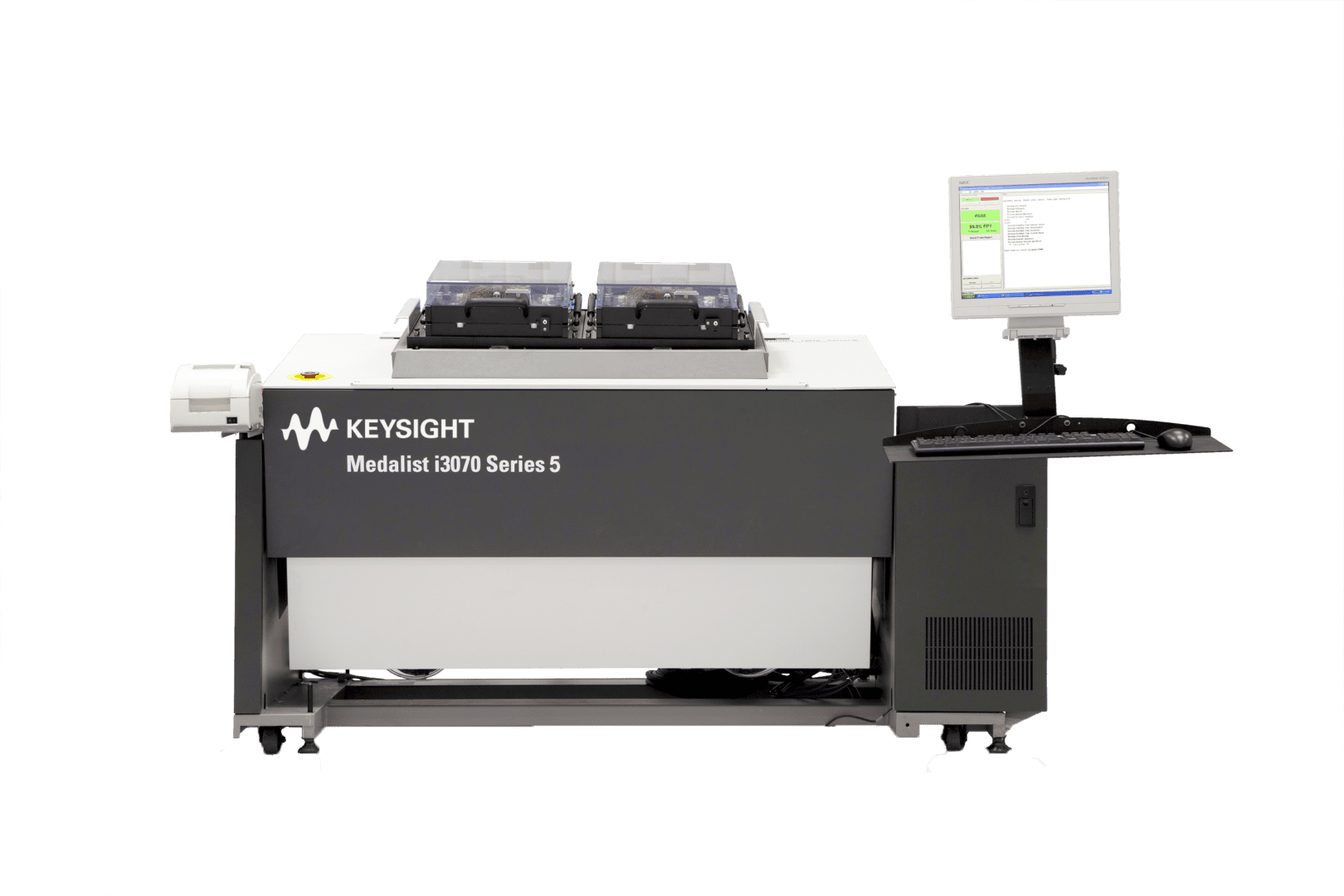

The backbone of ICT is the tester. SSP currently uses Keysight Technologies 3070 ICT testers (formerly Agilent 3070 and HP 3070). With these testers, it provides the foundational test and measurement equipment in order to facilitate testing. With this resource, OEMs and CMs alike address various electronic manufacturing test access and coverage issues in the constantly evolving and complex PCBA industry.

SSP's Facility currently has:

- 3 Fully-loaded Keysight 3070 Series 5 Testers

- Experience using Keysight's High Node Count (HNC) Adapter

- For complex PCBAs having greater node counts than what is natively supported on the Keysight 3070, a HW adapter is used to extend the capacity of the in-circuit tester to support ICT projects of 5,280+ nodes

ICT Fixtures

ICT fixtures are the necessary intermediaries between the software programming and the ICT testers to conduct the tests. Fixtures involve spring loaded probes on a "bed of nails" fixture, making strong contact between the PCBA's test points and the probes. There are many variations of ICT fixtures such as:

- Single stage vs dual-stage fixtures (sometimes even tri-stage fixturing)

- Clamshell fixturing (having test points on top and bottom of PCBA)

- Wired vs wireless fixtures

- Pneumatic vs vacuum box fixtures

- Small fixture size vs large fixture size

- 1 DUT (device under test) or multi-up DUT (of the same board) per fixture

- Multiple different DUTs on a single fixture

- Loopback actuations

SSP is experienced in working with leading fixture suppliers with a variety of the above setups to ensure your PCBA is tested with the right approach in maximizing test coverage and providing a quality solution.

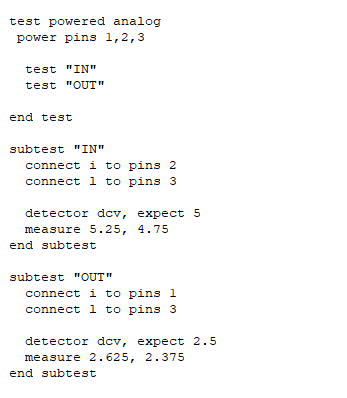

ICT Software Programming

SSP's core is software programming. We are experts in ICT programming for PCBA's ranging with few nets to more than 10,000+ nets on the most complicated designs. OEMs and CMs look to our experience working with leading edge electronic technology to program highly efficient and reliable solutions.

SSP has its standard ICT SOW which checks the common manufacturing defects such as: shorts, opens, missing component, misplaced component, etc. As an alternative, if a customer supplies SSP their SOW, we are able to program to those specs as well.

In addition to standard ICT programming capabilities, here's a list of SSP's advanced ICT capabilities:

- LED Tests

- ISP rogramming

- Flash programming

- EEPROM programming

- AC to DC converter testing

- Case by case functional tests

Whether assistance is needed for 1 PCBA, multiple PCBA's, or a family of PCBA's for a product line, SSP is here to deliver quality ICT turnkey systems in a timely manner.